Top 7 Formwork Design Best Practices

Efficient formwork design is crucial for the success of any construction project. Proper formwork not only ensures structural integrity but also influences the quality and speed of construction. In this article, we’ll delve into the top seven best practices for formwork design that can enhance construction efficiency and safety.

Understand Project Requirements: Before designing formwork, thoroughly analyze project requirements including structural loads, dimensions, and site conditions. Consider factors such as concrete placement methods, curing requirements, and expected finish quality. This understanding lays the foundation for an effective formwork design strategy.

-

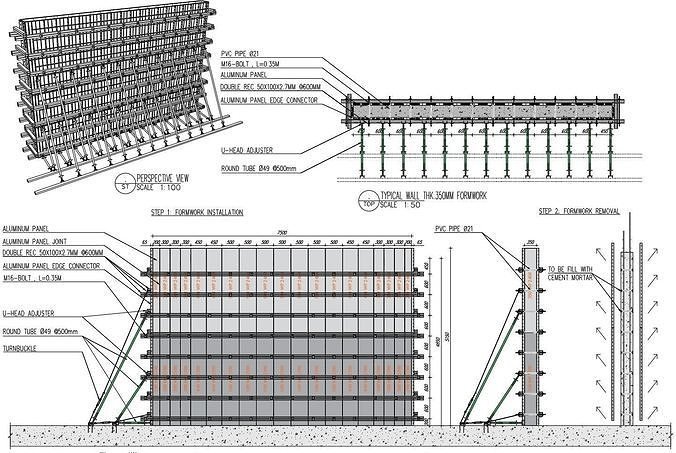

- Select Suitable Formwork Materials: Choose formwork materials based on project specifications, budget, and durability requirements. Common materials include timber, steel, aluminium, and plastic. Evaluate each material’s strength, weight, reusability, and compatibility with construction methods to make informed decisions.

- Prioritize Safety: Safety should be a primary consideration in formwork design. Ensure formwork systems are engineered to withstand anticipated loads and environmental conditions. Implement safety measures such as guardrails, access platforms, and fall protection systems to safeguard workers during formwork installation, concrete pouring, and dismantling.

- Optimize Formwork Geometry: Design formwork with optimal geometry to minimize material usage, labour costs, and construction time. Utilize standard formwork dimensions whenever possible and incorporate modular components to facilitate assembly and disassembly. Additionally, employ adjustable formwork systems to accommodate variations in structure geometry and dimensions.

- Enhance Formwork Stability: Maintain formwork stability throughout the construction process to prevent structural failures and ensure worker safety. Anchor formwork securely to the ground or supporting structures using appropriate fastening methods. Employ bracing, ties, and lateral supports to resist lateral loads and minimize formwork deflection.

- Consider Formwork Reusability: Maximize the reusability of formwork components to reduce waste and construction costs. Design formwork systems with interchangeable parts and modular components that can be easily assembled and disassembled for reuse on multiple projects. Implement proper maintenance practices to prolong the lifespan of formwork materials and components.

- Implement Quality Control Measures: Implement rigorous quality control measures to verify formwork integrity and compliance with design specifications. Conduct inspections before, during, and after formwork installation to identify any defects or deficiencies. Ensure formwork components are properly aligned, braced, and supported to maintain structural stability and concrete quality.

Effective formwork design is essential for achieving construction project objectives efficiently and safely. By following these seven best practices, engineers and contractors can optimize formwork performance, enhance project outcomes, and mitigate risks associated with formwork construction. Prioritizing proper planning, material selection, safety measures, and quality control processes lays the groundwork for successful formwork implementation and project completion.